用途和特點

液壓開門蒸壓釜的快開門裝置主要由釜蓋法蘭、釜體法(fǎ)蘭和分瓣卡箍組成。該(gāi)結構無需對釜蓋法蘭和釜(fǔ)體法蘭銑齒,節約生產周期,提高設備壽命;液壓開門(mén)蒸壓釜由液壓缸(gāng)驅動釜門(mén)的開、關,提高生產效率,降低勞(láo)動強(qiáng)度,改善工人操作環境。

液(yè)壓開門蒸壓釜主要用於灰砂(shā)磚、粉煤灰磚(zhuān)、加氣混凝土(tǔ)砌塊、新型輕質牆體(tǐ)材料,混凝(níng)土管樁等建築製(zhì)品的蒸壓養護,經過蒸養,使製品獲得高強度。產品除應用於矽酸鹽建築製品外,還(hái)可應用於化工、醫藥、橡膠、木材、石(shí)膏、玻璃、保溫材料、紡工、軍工等領域。

FUNCTION AND FEATURES

Fast door-opening device of hydraulic pressure door-opening autoclave consists of flange for autoclave cap, flange for autoclave body and sectioning clamp. No need to cut teeth for this structure, so the production time is saved and the life of the equipment is improved. Hydraulic cylinder drives the opening and closing of the autoclave door, which improves the manufacturing efficiency, decreases the labour intensity and betters the operation environment.

Hydraulic pressure door-opening autoclave applies to the steaming and maintenance of such building products as lime-sand brick, fly-ash brick, aerated concrete block, light wall material and concrete tubular pile. After steaming, the strength of the product is improved. Beside silicate building product, the product is applicable to many fields, such as chemical industry, medicine, rubber, wood, gypsum, glass, insulating material, spinning industry and military industry.

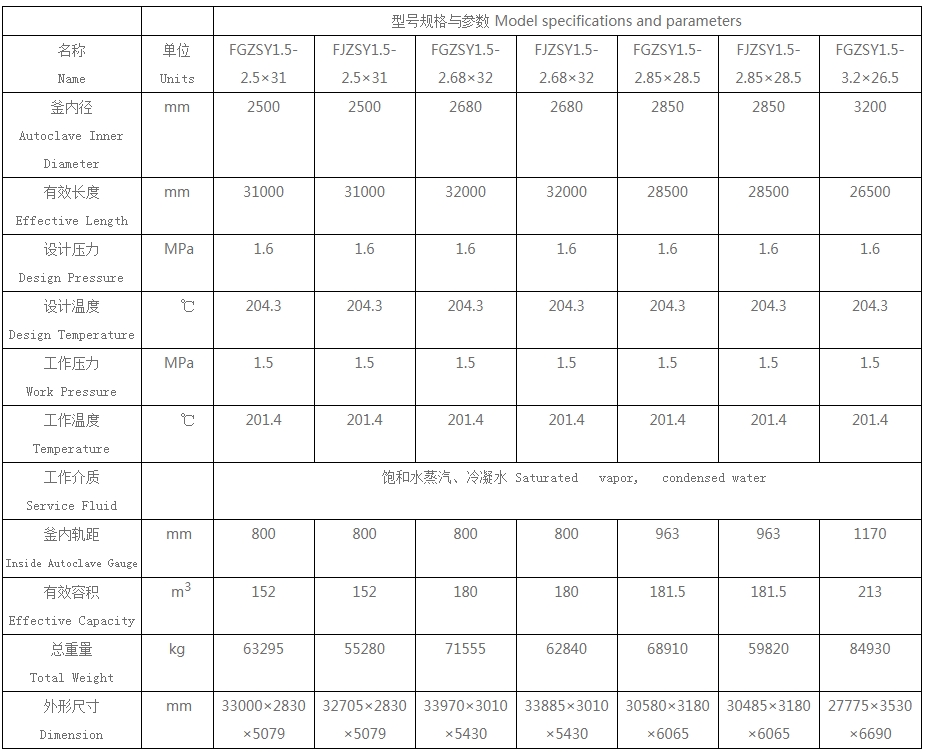

型號規格與參數

以下型號為我公司標準(zhǔn)規(guī)格產品型號。釜體長(zhǎng)度、釜內軌高、軌距可以(yǐ)根據用戶要求進行適當調整。

Model specifications and parameters

The above models are the standard models of our company. The length of the autoclave body, the rail height and track gauge inside the autoclave are customized.